What Is The Right Grain Sweep for Your Farm?

A bin sweep auger is an essential piece of equipment for any grain-handling farm. Sweeps make the processes of cleaning and maintaining grain bins simple, so you save valuable time, effort and money. Finding the right sweep auger for your organization can help you dramatically boost productivity and profitability.

Types of Grain Sweeps

Farmers can choose from several varieties of sweep augers for grain bins. One of the main differentiating factors in bin sweeps is how they operate. Bin sweeps get power in two ways:

- Direct gear drive (DGD): A DGD sweep gets power from the bin unload. To use it, you power off the unload, engage the sweep and turn the system on.

- Separate motor: This type of sweep contains its own motor, so it does not have to connect to your grain bin unload auger.

The following types of sweeps can operate using either power input. Each offers various advantages depending on your farm’s needs.

Grain Sweep Auger

A sweep auger is the oldest type of bin sweep still in use today. It consists of a rotating helical screw component — also called the flighting — within a larger trough or tube. A connected motor turns the screw, which picks up grain and moves it through the bin.

Sweep augers are most useful in bins where grains may settle or become compacted.

Paddle Sweep Auger

Paddle sweeps are relatively new. Available at speeds up to 5,500 bushels per hour (bph), this type of sweep uses a heavy-duty rubber paddle chain conveyor that transports grain from the bin’s outer edges to the center sump. This configuration helps keep the bin floor clean.

Compared to the traditional sweep auger, paddle sweeps are less likely to cause damage to your grain. Many can also work themselves free, so you can completely submerge them in grain without problems.

U-Trough Grain Sweep

U-troughs are increasingly popular among grain handlers because they fit under the aeration floor. This configuration allows the sweep to relieve pressure as the grain moves, reducing the risk of damage to the grain.

This type of sweep often comes with an adjustable flight, which allows you to expand the sweep to fit your bin. It also features dual-action sweep wheels, which sweep away the outer grain while moving the unloader through the bin.

Carry-In Grain Sweep Auger

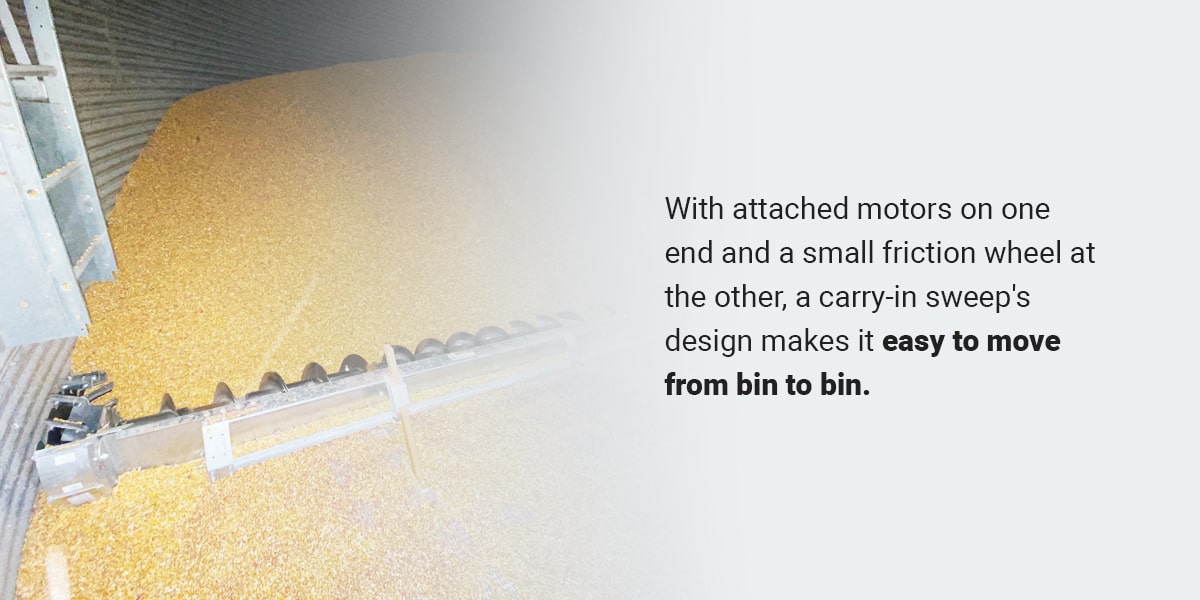

With attached motors on one end and a small friction wheel at the other, a carry-in sweep’s design makes it easy to move from bin to bin. While carry-in sweeps are light and portable, they’re becoming less common due to increasing bin sizes.

When you drop a carry-in sweep into the bin’s center hole, its friction drive wheel allows it to move through the bin. A carry-in sweep’s capacity can range from 800 to 3,700 bph, depending on the model. Sweeps with higher capacities are best suited for use in commercial applications.

Zero-Entry Grain Bin Sweep

Because you operate a zero-entry commercial sweep from outside, it can significantly reduce the risks involved with entering a grain bin. Additionally, high-quality zero-entry sweeps are usually strong enough to handle damaged grain without requiring workers to dislodge it manually.

In addition to reducing your risk, a zero-entry sweep offers benefits that include the following:

- Time savings: A powerful zero-entry sweep can keep working round the clock, condensing what would typically be a two- to three-day task into only a few hours.

- Increased efficiency: Because you can sweep bins faster, you can clean them more often. More frequent sweeping allows you to eliminate out-of-condition grains at the bottom of your bin, which can halt regular bin-sweeping operations.

- More bin usability: Zero-entry sweeps completely clean bins, allowing you to use them for non-grain crops if needed.

- Less need for training: Since workers can avoid entering the bin, training them on traditional grain sweeping protocol is less necessary.

In some cases, you may be able to retrofit your existing bin sweep with new equipment to upgrade it to a zero-entry sweep.

Grain Sweep Safety

Grain sweeping is a dangerous task. Workers must take the proper precautions to protect themselves, as a misstep could lead to serious injury or even death.

OSHA’s standards for grain handling facilities lay out the required conditions for workers to safely enter a grain bin with an engaged sweep auger:

- Safety permit: Before anyone can enter the grain bin, workers must obtain an entry permit verifying that all relevant safety precautions are in place.

- Lock-out or tag-out procedures: Workers must de-energize and lock or tag out the subfloor auger and all grain entry points before entering the bin.

- Security grates and guards: All mechanical hazards must be secured with grates or guardrails, including the subfloor auger sumps and sweep augers. Failure to install guards can result in lost limbs or death.

- Supervision: Grain sweeping should always be a two-person operation. One worker observes from outside the bin while the other works inside. Both workers must maintain constant contact through sight, voice or radio. Additionally, the observer must know who to contact if an emergency occurs.

- Safe conduct: Workers must avoid using their hands, legs or other body parts to dislodge anything caught in the auger while it is energized. Instead, they should turn off the auger and remove the blockage before continuing.

It’s also essential for workers to wear the proper personal protective equipment (PPE) while working in a grain bin. Respiratory and hearing protection like N95 respirators and earplugs can help prevent serious physical harm.

Benefits of Grain Bin Sweeps

Bin sweeps are essential pieces of equipment for any grain-handling operation. The benefits of using on-farm and commercial grain bin sweeps include the following:

- Enhanced productivity: As farms scale up grain production, larger bin sweeps have become a necessity for maintaining high productivity and efficiency.

- Increased safety: Permanent sweeps eliminate the need for workers to enter the bin, reducing the risk of serious injury.

- Cost savings: An on-farm sweep enables you to store your grain yourself, which is more cost-effective than holding it in a commercial facility. It also offers you more flexibility to respond to market changes in ways that will save your organization money.

Contact TAM Systems About Sweep Augers for Grain Bins

If you’re looking to add a bin sweep to your organization or need assistance finding the right sweep for your needs, TAM’s knowledgeable team is here to help. At TAM, our goal is to provide the best equipment for your unique needs. We have various grain bin sweep augers for sale from reliable brands such as Brock, Hutchinson and GSI.

Whether you need an on-farm sweep or a large-scale commercial solution, we can help you find what you need at the right price. Contact us today for more information about which sweep auger makes the most sense for your organization.